About COREX

Thermoplastics cores for paper and tissue industry

Thanks to its plant being located at the heart of the world's main tissue district of Lucca, Idrotherm 2000 has been able to develop COREX® in close partnership with the biggest paper manufacturing companies to fit their needs. At present, a dedicated division is in force in Idrotherm 2000 relying on the expertise gained through the years in this field.

Manufactured with special thermoplastic compounds, COREX® was patented by Idrotherm 2000 in 1998 and thus made available on the market, since then revolutionising the tissue industry.

Contact usCOREX & Environment

Reduce Carbon Footprint with COREX BS

COREX® is distinguished by high values of impact resistance and tensile stress. Even if submitted to remarkable mechanical stress no long term deformability is shown in modern paper rolling machines.

COREX® BS can be manufactured using raw materials sourced from alternatives to traditional fossil sources, such as oilseed crops (corn, rapeseed, palm, etc.) or waste and residues from vegetable oils in the food industry or from cellulose processing (tall oil). This allows for a reduction in the carbon footprint of the final product compared to the product obtained through the fossil-based process.

Why COREX

Benefits of choosing COREX

Low Environmental Impact

The polymeric materials employed for COREX® are completely atoxic and are 100% recyclable with lower carbon footprint compared to cardboard (reduced disposal of wastes).

Savings

Considerable financial saving is provided by COREX® if life-cycle costs are compared to cardboard alternatives

Long life cycle

COREX® is characterized by long-lasting usage: more than 180 winding cycles compared to the industry average 6-8 of a traditional cardboard core.

High precision design

COREX® can be produced in different colours and with highly precise dimensions to suit different technologies of winding shafts. Lengths can be chosen according to end users needs.

Mechanical strength

Considerable financial saving is provided by COREX® if life-cycle costs are compared to cardboard alternatives.

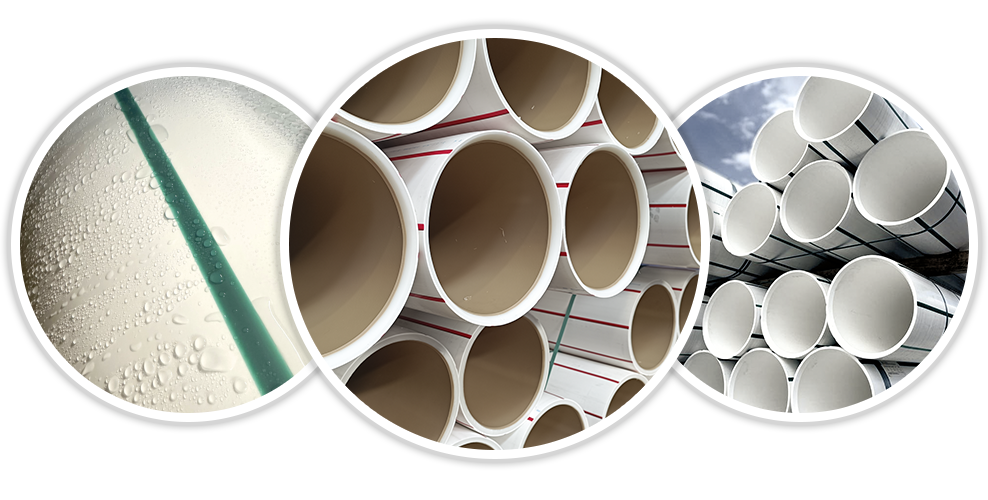

UV resistant

The plastic compounds employed for COREX® are UV radiation resistant, thus allowing open air storage and avoiding any problem related to moisture, which inversely can affect cardboard cores.

Why COREX

Advantages of plastic cores

The special polymeric compound of COREX® is designed to resist to mechanical stresses occurring in standard uses. COREX® cores can endure hundreds of rotations as opposed to cardboard cores

The long life of COREX® cores allows considerable savings when compared to the costs of cardboard alternatives: the investment is generally amortized within 12 months. COREX® cores can be stored outside under all weather conditions and do not degrade or delaminate even if notched with cutting tools.

Bespoke colours (also with longitudinal coextruded stripes) and markings aid traceability and identification.